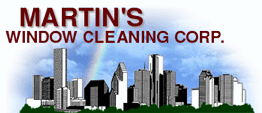

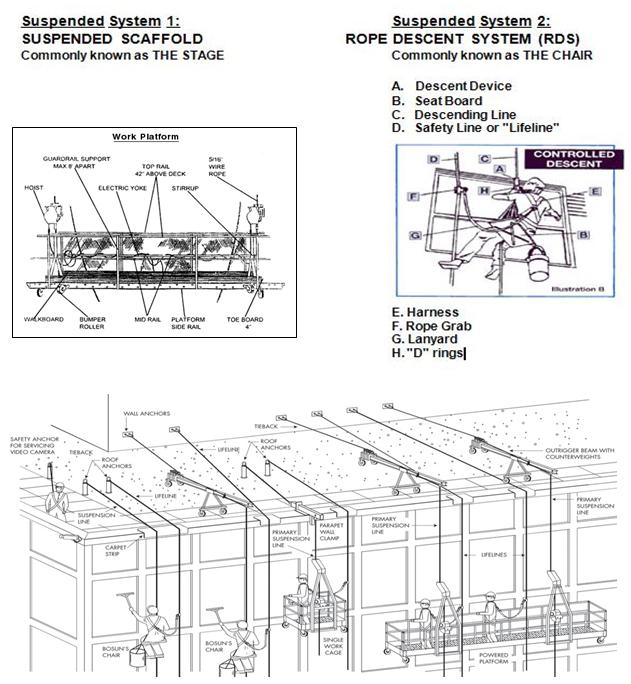

Support System – Keeps the suspended equipment from falling. Counter weighted rolling outrigger system attached to anchors with a minimum breaking strength of 5000 pounds.. The counter weighted load will be calculated at least the minimum ratio allowed which is four to one. This system may include: outriggers (stationary or rolling), weights, roof cars, or davit systems. This system always includes an independent anchor for the working line and an independent anchor for the life line that relies on the strength of the building.

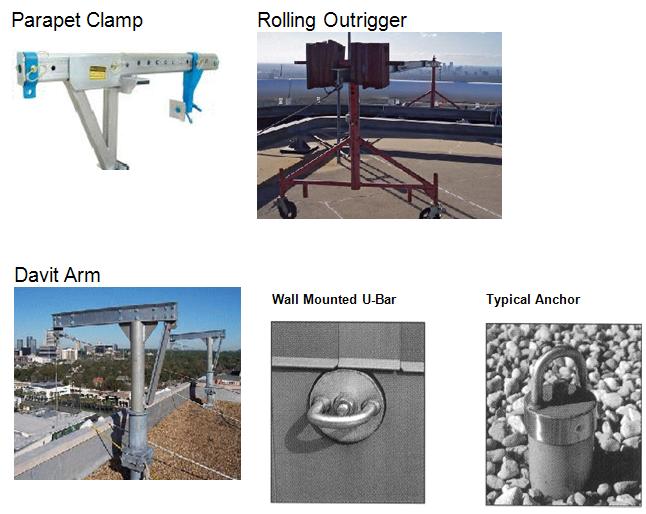

Suspended System–All equipment that hangs from the support system. A 30′ aluminum walkboard (deck) with two 1000 pounds maximum rated load hoists mounted on each end. 5/16″-8.3mm diameter 6/19 Seale construction IWRC, right regular lay, preformed, improved plow steel wire rope are threaded through the hoists and terminated at the suspension eye bolt in the end of the outrigger beam. The motors are powered by 220 Volt, single phase, 6-amp current supplied by the building. This system may include a powered stage, wire rope, electrical cord, hoists, Rope descent system (RDS), tools, equipment and the worker(s). This system always includes the fall arrest equipment.

Fall Arrest System – Protects the life of a worker in the event of a fall. Each worker on the platform will have his own independent fall-arrest equipment consisting of a full body harness, a shock absorbing lanyard, a 5/8″ rope grab attached to a static 5/8″ E-Z Bend life line with a minimum breaking strength of 13,000 pounds secured to an anchor independent from the suspended system. The anchor must be able to hold at least 5000 pounds. Approved equipment for a fall arrest system is the lifeline anchorage, the lifeline (safety line), a shock absorbing lanyard, a rope grab and a full body harness.